Museum Improvements

National Museum of Mathematics

While working at the National Museum of Mathematics I have had my hands, arms, or sometimes entire body inside of nearly every exhibit in the museum. In some cases this work simply involved repairing or replacing motors, LEDs, buttons, relays, circuit boards or other functional components. But in others I took the initiative to make more significant design changes to the exhibits to improve their functionality and increase their longevity. These are some examples of this sort of work.

Pattern Mesh Spring Mechanism

Opening up this exhibit I discovered that its initial functionality to “grip” the pattern discs with its rotating rubber wheels had long ago broken, and a shoddy, improvised modification was the only reason it was not completely nonfunctional. I completely redesigned and fabricated a custom spring mechanism to return the exhibit to full, proper operation.

Twist and Roll Reproduction (WIP)

The rubber shapes in this exhibit require regular replacement, and in order to be able to reproduce them in-house I 3D printed plastic versions of the shapes and am currently sanding and finishing them in order to make silicone molds that allow for easy reproduction.

Custom COVID-19 Retail Shield

I designed and fabricated this custom COVID-19 safety shield for the museum retail desk.

Ball Bot Height Adjustment Knob

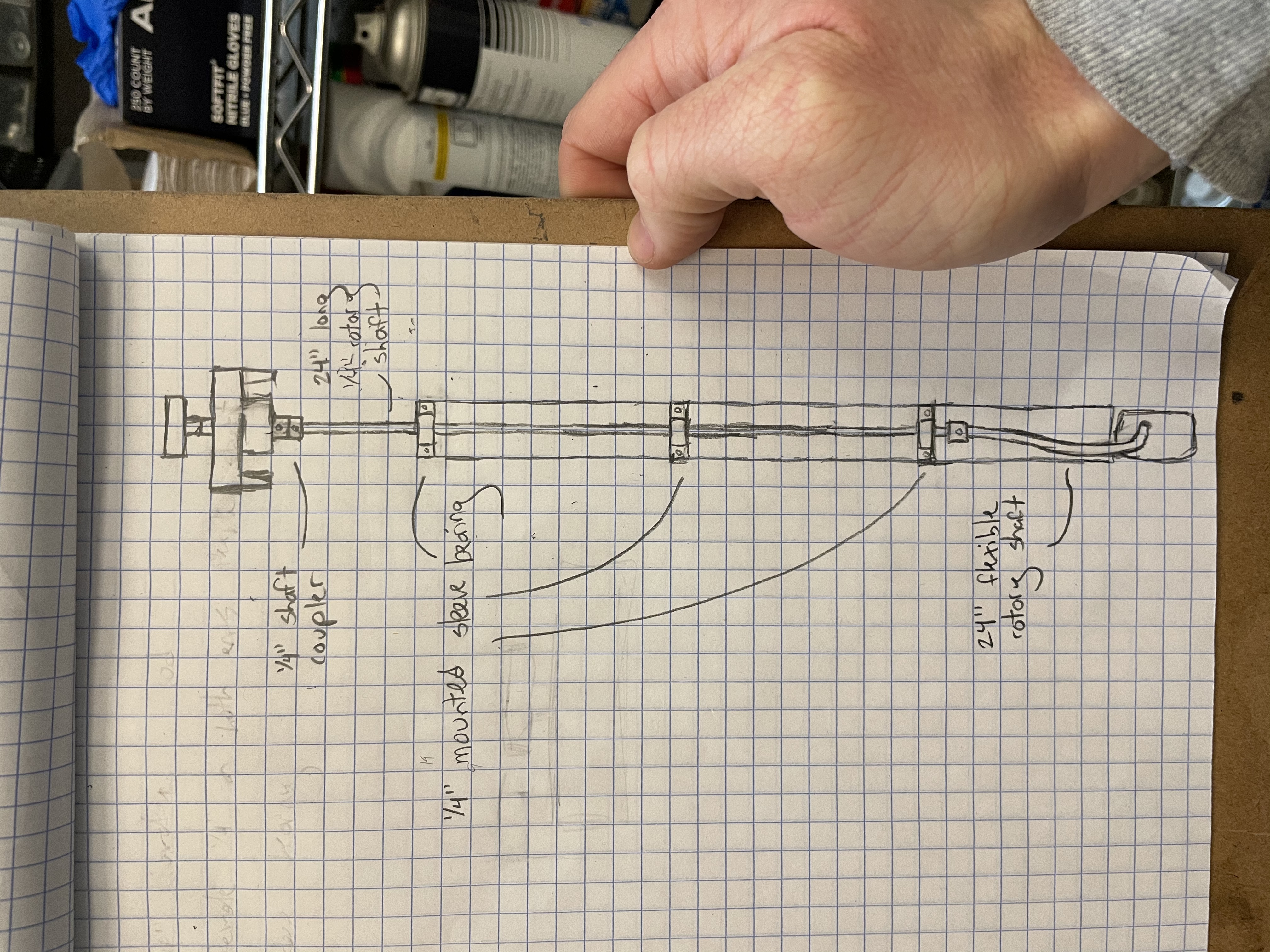

To improve the reliability and safety of the height control on the Hoop Curves ball launcher, I designed this new system of rotation transmission and installed a custom speed limiter.